SEARCH

Enter your search term below:

Close

Enter your search term below:

WORLD LEADING BUSINESS SUPPORT

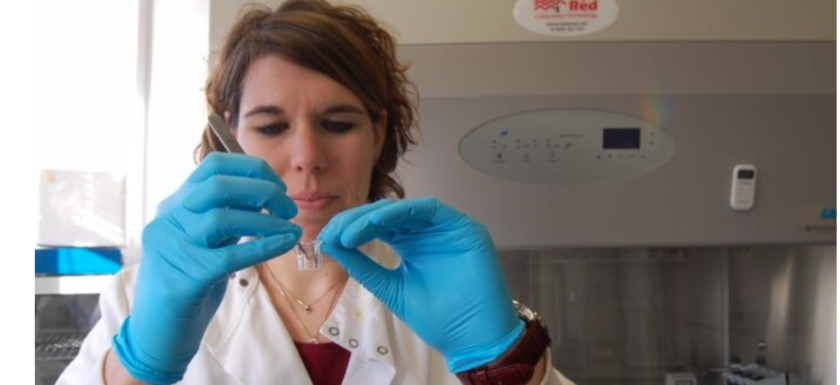

CellRev aims to revolutionise the way cells are grown in the lab. It is developing ground-breaking technologies to make the culturing of cells more efficient and affordable. The process is based on the novel concept of a continuous cell culturing system which has a higher yield, smaller footprint and lower input requirements than traditional batch technologies. Its technologies can be used for various cell types and applications, making it suitable for any companies active in the culturing of cells regardless of whether they are active in the field of cultured meat, cell therapy or biologics.

April 2018

Started on ICURe programme

December 2018

Company formed

May 2019

Innovate UK grant: £166k

July 2019

Spin out completed

July 2019

Pre-seed investment raised

November 2019

North East Innovation R&D funding: £140k

March 2020

COVID-19 Continuity grant awarded: £90k

January 2021

£1m investment raised

January 2022

Hired Chief Commercial Officer

February 2022

£1.75m investment raised

March 2022

Rebranded from Cellular REvolution to CellRev

Januray 2023

Entered into pre-commercialisation phase

“We joined the ICURe programme in early 2018 to address the challenges in the market and to start speaking to people to make sure what we were developing was really going to be useful to them – would they purchase it? I also wanted to make some connections and start to build relationships, it’s always more powerful to do that in person.”

“I thought the ICURe programme was fantastic. The biggest thing I got out of it was the confirmation that our technology was important and that the markets were interested in it. It gave us the starting point that we needed to prioritise what we were working on and where our focus should be. The cultured meat market was just taking off during the period we started on ICURe and it was so important for us to be in the right place at the right time to capitalise on that.”

“In 2019 the company raised pre-seed funds through a mixture of non-dilutive grants and direct investments, which really helped us push the company forwards. When we started, we had a proof of concept on the technology, but it’s different from having the real thing. We developed a working prototype and validated the technology, despite the challenges brought by the pandemic and having restricted access to the lab. In 2021 we raised £1m from a set of strategic investors to accelerate the development of our products and make a true innovative impact on the way cells are grown.”

“In January 2022 we hired Chris Green, a Chief Commercial Officer, now the CEO, which has been crucial in defining our strategy and working towards commercialisation. We raised an additional £1.75m in investment, and we have grown the team to 14 people. We undertook a full rebrand in 2022 and renamed to CellRev with a new logo and website.”

“Having now validated the technology, we need to show that it actually works in a prototype that can then be used by potential customers. In 2023 we will be starting external validations in collaboration with companies, which involves testing their cells in our labs for compatibility with our technology. Once we have demonstrated that it works, they may purchase our technology.”

“We will be entering into a pre-commercialization stage at the end of the year, and then in 2024 we plan to fully commercialise our bioreactor. This will be sold as an R&D bundle – the hardware along with the consumables needed to make it work. The short and medium term plan is to get the hardware into the market at a small scale (around 15 to 50 litre reactor size) for people to get accustomed to the technology, as there will be an adoption phase. Longer term within 5-6 years, we see the highest value at a more industrial scale (around 2000 litres reactor size), and here we plan to licence our IP.”

Martina Miotto, Co-Founder and CSO

CellRev

Close